2007 / PS62 Garden Shed

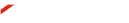

Against the house? Against the fence? The 2007 / PS62 garden shed has a roof that slopes to the front enabling it to sit hard against the wall. The perfect space saving solution for storing a large range of household items.

- Width 2.02m

- Depth 0.685m

- Height 1.96m

- Pack Height 0.160m

- Pack Width 0.860m

- Pack Length 2.195m

- Pack Weight 45kg

- Door Opening 1.440m

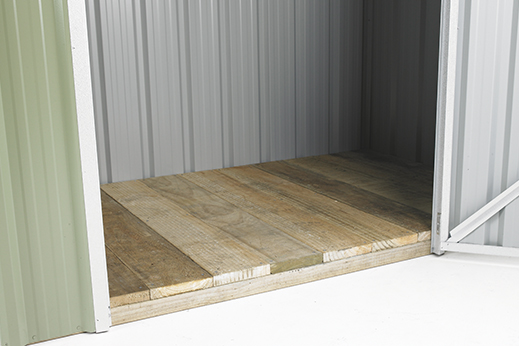

- Roof Type Skillion Roof

Getting To Know The 2007 / PS62

Your review of 2007 / PS62 Garden Shed

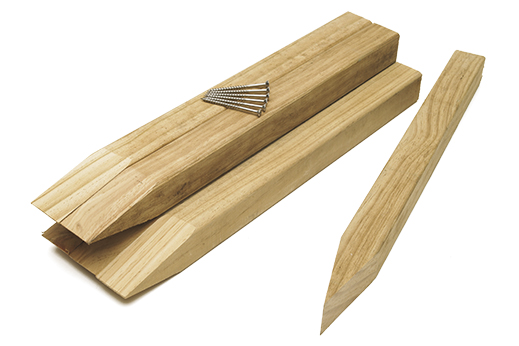

Semi Timber Frame Range Features

In this video Justin points out the features of our Semi Timber Frame range of sheds.

Semi Timber Frame Shed Assembly Video

In this video Keith will show you how to build a Duratuf Semi Timber Frame shed like a professional. To be used in conjunction with the instruction manual, Keith’s practical tips and tricks will make your assembly experience that much simpler. Giving you visual guidance through sections that seem tricky on paper, and helping you achieve a flawless end result.

FIND A RETAILER